SEEGER RINGS AND WASHERS

Details make perfection

In addition to high-quality material and proper processing, the design of the retaining rings also plays a critical role. In the end, the design of the groove determines whether the retaining ring meets all requirements and ensures smooth operation. Our SEEGER ring meets the most discerning demands.

Design of the groove

- The ring groove absorbs the forces transmitted from the retained SEEGER machine component and must be designed accordingly.

- The groove diameter d2 (see figure) determines whether the rings are seated in the grooves with the necessary preload. This preload is always required when large mass forces occur in the ring plane which oppose the stress of the rings, e.g. centrifugal forces at high shaft speed.

- The groove depth “t” can be reduced in favor of an increased prestress. In designs where such mass forces do not occur, the groove depth can be enlarged.

Shape of the groove

The grooves of SEEGER retaining rings are generally rectangular.

It can be rounded at about 10% of the ring thickness on the load side (Figure a) or

slanted towards the relieved side (Figure b).- If sharp-edged rings are used, it is recommended to systematically round the grooves on the load side (Figures c and d), allowing the ring to make optimum use of the groove surface.

- Of course, the groove can also be shaped in such a way that the notch effect of the ring is significantly reduced. In this case, we usually refer to a so-called relief groove (Figure e).

Notch effect of the groove

- Matching sharp-edged grooves for Seeger retaining rings, necessarily lead to a notch effect.

- For components made of materials with a notch sensitivity of CK 45 Rm = 650 N/mm2, this may lead to higher stress and increased wear.

- The average notch effect figures for rectangular grooves are as follows:

Shaft diameter 30 mm: ßK = 2.24

Shaft diameter 80 mm: ßK = 2.60

These notch effect figures can be significantly reduced by rounded grooves or a relief groove.

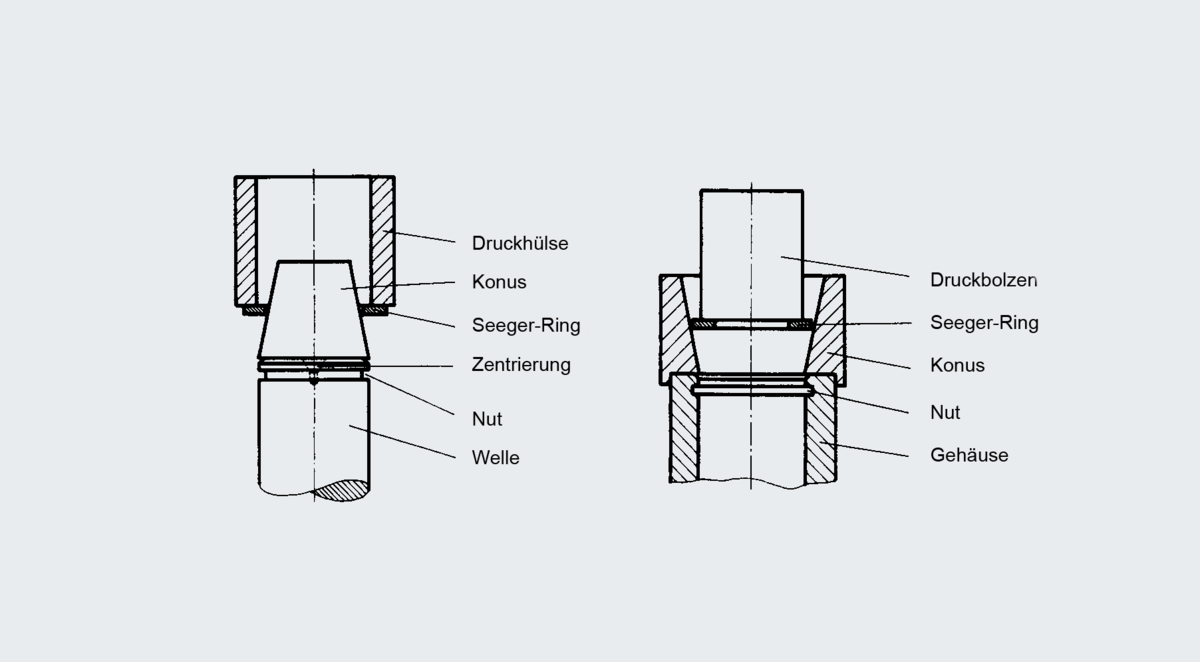

Positive radial retention

- When viewed axially, the SEEGER ring joint is a positive retention. Radially, however, the elastic ring is only firmly seated on the groove (Figure a).

- SEEGER snap rings/circlips, V-rings and K-rings as well as special versions of the SEEGER ring to DIN 471/472 are also held radially positive (Figure b).

- Positive radial retention is especially advantageous for large axial forces and high demands, because

- the ring cannot work its way out of the groove

- deeper grooves may be used as there is no need for preloading

- as a result the load bearing capacity of the groove increases

- the shaft rings are no longer speed-dependent

Compensating axial play

Axial play in machine parts by virtue of its design cannot be compensated for with classic SEEGER rings. With type AL and JL retaining rings,however, an elastic compensation of play is possible thanks to a springing effect of the rings.

If elastic compensation is not permissible in bores, the use of SEEGER type JB beveled rings is recommended, which permit play-free retaining of the machine component.

To allow for a rigid reduction of the play in steps, SEEGER rings and

washers are available in various thicknesses. The step range and thickness tolerance of the grounded rings are generally between 0.02 and 0.05 mm. SEEGER support washers are also available with stepped thicknesses – individually adapted to customer requirements.